For this reason, the hairpin winding method is rapidly applied to the industry. Among them, the most efficient method is to increase the load factor of the stator winding.

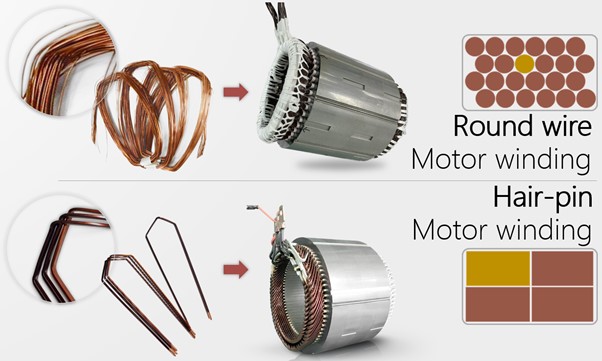

Though motors noramlly use internal permanent magnets for torque, power, and efficiency, they can instead use an ac induction coil for simpler controls and lower cost. Therefore, EV makers are trying to increase the efficiency of the motor by reducing copper loss, which is the biggest loss of the motor. To simplify the engineering involved in adding an HVH motor to a vehicle, the motors meet SAE standards and use SAE bellhousing and transmission bolt patters. Taycan Turbo S: Electricity consumption combined: 26,9 kWh/100 km CO2 emissions combined: 0 g/kmChapter 4The secret to electric power from Porsche: hairp. And HVH motors offer a 22% reduction space requirements and 13% less mass than conventional motors with the same performance characteristics. In tests, an HVH internal-permanent-magnet (IPM) motor generated 27% more torque and 37% more power compared to the same sized round-wire- winding IPM motor. The HVH windings are well-suited to liquid cooling which enhances performance and reliability. This winding method offers the advantage of automated winding process. The winding scheme also makes it easier to strengthen the construction at critical connections between conductors. Hairpin winding has been widely used in electric motors in the automotive sector. This creates a shorter end-turn space, thereby reducing heat and improving torque and power density, as well as reducing motor size. Several layers of these interlocking hairpins have better slot fill than conventional windings (up to 70% for HVH compared to 40% for round windings). Eddy Current Losses in a Hairpin Winding for an Automotive Application. Proof of this are the many 1000 winding testers at enthusiastic customers all over the world. And to do that, manufacturers are replacing the older types of heavy, round wire motor windings with hairpins: solid, preformed rectangular bars that are intertwined and locked into place. Unlike convention round-wire windings, these motors use precision-formed rectangular or hairpin wires. One key to achieving that goal is optimizing the amount of copper used in the stator core slots.

The key to these HVH motors are their High-voltage Hairpin stator windings. Remy off-the-shelf hybrid motors incorporate proprietary High Voltage Hairpin winding technology and unique cooling strategies that produce the highest. designed a line of off-the-shelf devices that are said to have the highest efficiencies and power densities of any motor/generator on the market. To meet the demand for drive motors / generators needed for hybrid vehicles, engineers at Remy International Inc.

0 kommentar(er)

0 kommentar(er)